Tablets and compaction

Göran Alderborn

Chapter contents

Technical problems during tableting

Tablet production via granulation

Tablet production by direct compaction

Sublingual tablets and buccal tablets

Prolonged-release and pulsatile-release tablets

Uniformity of content of active ingredient

Fundamental aspects of the compression of powders

Mechanisms of compression of particles

Evaluation of compression behaviour

Fundamental aspects of the compaction of powders

Compactability of powders and the strength of tablets

Post-compaction tablet strength changes

Relationships between material properties and tablet strength

Key points

• Tablets of different types represent collectively the dominant type of dosage form.

• Tablets are used for oral administration for both systemic and local drug treatment.

• Several categories of tablets exist that are used in different ways, e.g. swallowed whole or retained in the mouth during the release of the drug.

• Tablets are normally formed by powder compression, i.e. the forcing of particles into close proximity by the application of mechanical force.

• Besides the active ingredient, tablets normally consist of a series of excipients that are included to control biopharmaceutical and other quality attributes, as well as to aid the manufacturing of the tablet.

• The release of the active pharmaceutical ingredient is a key product attribute and can be controlled by the formulation to achieve immediate-release, delayed-release or prolonged- release of the drug.

• In the manufacturing of tablets, a series of unit operations are normally used, including mixing and granulation of active ingredient(s) and excipients.

• In the manufacturing of tablets, a number of technical problems can arise, such as high weight and dose variation, low mechanical strength, capping of the tablets, adhesion and high friction.

• The success of a tableting operation is related to the properties of the powder intended to be formed into tablets and also to the design and conditions of the press and the tooling.

• Important tests of quality attributes of tablets include tablet disintegration and dissolution, tablet friability and tablet fracture resistance.

Introduction

The oral route is the most common way of administering drugs and among the oral dosage forms, tablets of various kinds are the most common type of solid dosage form in contemporary use. The term ‘tablet’ (from Latin tabuletta) is associated with the appearance of the dosage form, i.e. tablets are small disc-like or cylindrical specimens. The Latin name of the dosage form tablet in the European Pharmacopoeia (7th edn, 2011) is compressi, which reflects the fact that the dominating process of tablet fabrication is powder compression in a confined space. Alternative preparation procedures are also in use, such as mouldings and freeze drying. Tablet-like preparations prepared by freeze drying are sometimes referred to as oral lyophilisates. Moulding, i.e. the shaping and hardening of a semi-solid mixture of active substances and excipients, and freeze drying will not be further described in this chapter.

The idea of forming a solid dosage form by powder compression is not new. In 1843 the first patent for a hand-operated device used to form a tablet was granted. The use of tablets as dosage forms became of interest to the growing pharmaceutical industry but within pharmacies, the pill (a dosage form for oral administration formed by hand into spherical particles about 4–6 mm in diameter) remained the most popular solid dosage form for a long time.

A tablet consists of one or more drugs (active pharmaceutical ingredients) as well as a series of other substances (excipients) used in the formulation of a complete preparation. In the European Pharmacopoeia (7th edn, 2011), tablets are defined as ‘solid preparations each containing a single dose of one or more active substances. They are obtained by compressing uniform volumes of particles or by another suitable manufacturing technique, such as extrusion, moulding or freeze-drying (lyophilization). Tablets are intended for oral administration. Some are swallowed whole, some after being chewed, some are dissolved or dispersed in water before being administered and some are retained in the mouth where the active substance is liberated.’

Thus, a variety of tablets exists, and the types of excipients and also the way in which they are incorporated in the tablet vary. Other dosage forms can be prepared in a similar way, but are administered by other routes, such as suppositories.

Tablets are used mainly for systemic drug delivery but may also be used for local drug action. For systemic use, the drug must be released from the tablet, i.e. normally it dissolves in the fluids of the mouth, stomach or intestine, and thereafter the drug is absorbed into the systemic circulation, by which it reaches its site of action. Alternatively, tablets can be formulated for local delivery of drugs in the mouth or gastrointestinal tract, or can be used to increase temporarily the pH of the stomach.

Tablets are popular for several reasons:

• The oral route represents a convenient and safe way of drug administration.

• Compared to liquid dosage forms, tablets (and other solid dosage forms) have general advantages in terms of the chemical, physical and microbiological stability of the dosage form.

• The preparation procedure enables accurate dosing of the drug.

• Tablets are convenient to handle and can be prepared in a versatile way with respect to their use and the delivery of the drug.

• Finally, tablets can be relatively cheaply mass produced, with robust and quality-controlled production procedures giving an elegant preparation of consistent quality.

The main disadvantage of tablets as a dosage form is the problem of poor bioavailability of drugs due to unfavourable drug properties, e.g. poor solubility, poor absorption properties and instability in the gastrointestinal tract. In addition, some drugs may cause local irritant effects or otherwise cause harm to the gastrointestinal mucosa.

Quality attributes of tablets

Like all dosage forms, tablets should fulfil a number of product quality attributes regarding chemical, physical and biological characteristics. Quality issues relating to the final product are worth considering early in the development process (and thus early in this chapter) as they give an indication of the goal to be achieved during the development and manufacture of tablets.

The quality attributes that a tablet must possess can be summarized as follows:

1. The tablet should include the correct dose of the drug.

2. The appearance of the tablet should be elegant, and its weight, size and appearance should be consistent.

3. The drug should be released from the tablet in a controlled and reproducible way.

4. The tablet should be biocompatible, i.e. not include excipients, contaminants and microorganisms that could cause harm to patients.

5. The tablet should be of sufficient mechanical strength to withstand fracture and erosion during handling at all stages of its lifetime.

6. The tablet should be chemically, physically and microbiologically stable during the lifetime of the product.

7. The tablet should be formulated into a product acceptable to the patient.

In order to quantify these quality attributes, tests and specifications must be defined. Some tests and specifications are given in pharmacopoeias, such as dose content, dose uniformity, tablet disintegration, the release of the drug in terms of drug dissolution, and the microbial quality of the preparation. Another important quality attribute of tablets is their resistance to attrition and fracture.

Tablet manufacturing

Stages in tablet formation

The dominating technique of forming tablets (although alternative procedures are in use, as indicated in the definition of tablets in the European Pharmacopoeia, 2011) is by powder compression, i.e. forcing particles into close proximity to each other by confined compression. This enables the particles to cohere into a porous, solid specimen of defined geometry. The compression takes place in a die by the action of two punches, the lower and the upper, by which the compressive force is applied. Powder compression is defined as the reduction in volume of a powder owing to the application of a force. Because of the increased proximity of particle surfaces accomplished during compression, bonds are formed between particles which provide coherence to the powder, i.e. a compact is formed. Compaction is defined as the formation of a solid specimen of defined geometry by powder compression.

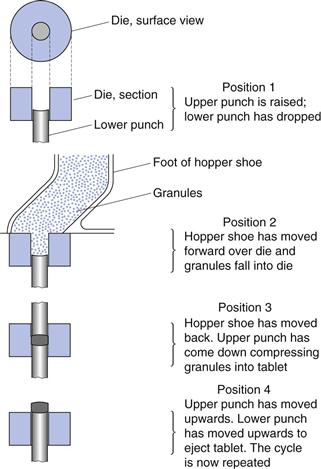

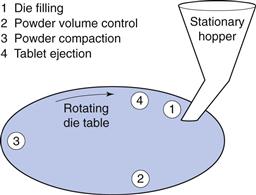

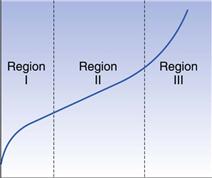

The process of tableting can be divided into three stages (sometimes known as the compaction cycle) (Fig. 30.1).

Die filling

This is normally accomplished by gravitational flow of the powder from a hopper via the die table into the die (although presses based on centrifugal die filling are also used). The die is closed at its lower end by the lower punch.

Tablet formation

The upper punch descends and enters the die and the powder is compressed until a tablet is formed. During the compression phase, the lower punch can be stationary or can move upwards in the die. After the maximum applied force is reached, the upper punch leaves the powder, i.e. the decompression phase.

Tablet ejection

During this phase the lower punch rises until its tip reaches the level of the top of the die. The tablet is subsequently removed from the die table by a pushing device.

Tablet presses

There are two types of press in common use during tablet production: the single-punch press and the rotary press. In addition, hydraulic presses are used in research and development work for the initial evaluation of the tableting properties of powders and prediction of the effect of scale-up on the properties of the formed tablets (scale-up refers to the change to a larger apparatus for performing a certain operation on a larger scale).

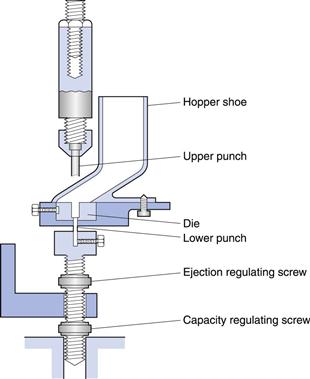

Single-punch press (eccentric press)

A single-punch press possesses one die and one pair of punches (Fig. 30.2), i.e. a set of tableting tools. The powder is held in a hopper which is connected to a hopper shoe located at the die table. The hopper shoe moves to and fro over the die, by either a rotational or a translational movement. When the hopper shoe is located over the die, the powder is fed into the die by gravitational powder flow. The amount of powder filled into the die is controlled by the position of the lower punch. When the hopper shoe is located beside the die, the upper punch descends and the powder is compressed. The lower punch is stationary during compression and the pressure is thus applied by the upper punch and controlled by the upper punch displacement. After ejection, the tablet is pushed away by the hopper shoe as it moves back to the die for the next tablet.

The output of tablets from a single-punch press is up to about 200 tablets per minute. A single-punch press thus has its primary use in the production of small batches of tablets, such as during formulation development and during the production of tablets for clinical trials.

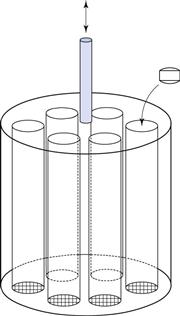

Rotary press

The rotary press (also referred to as a multistation press) was developed to increase the output of tablets. The primary use of this machine is thus during scale-up in the latter part of the formulation work and during large-scale production. Outputs of over 10 000 tablets per minute can be achieved by rotary presses.

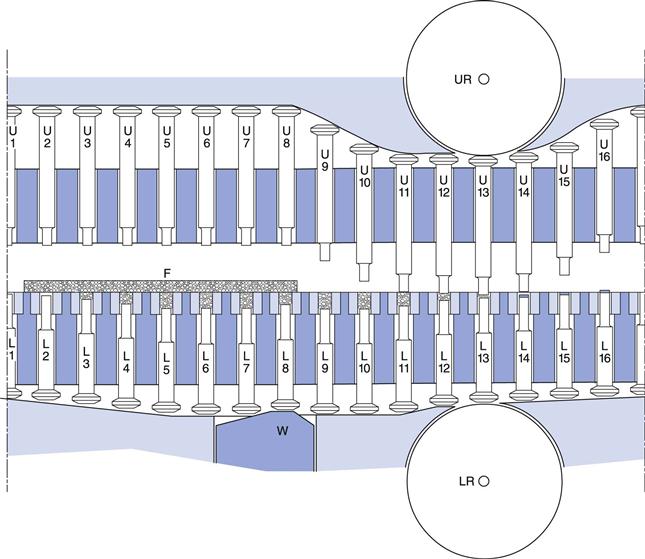

A rotary press operates with a number of dies and sets of punches, which can vary considerably from three for small rotary presses, up to 60 or more for large presses. The dies are mounted in a circle in the die table and both the die table and the punches rotate together during operation of the machine, so that one die is always associated with one pair of punches (Figs 30.3 and 30.4). The vertical movement of the punches is controlled by tracks that pass over cams and rollers used to control the volume of powder fed into the die and the pressure applied during compression.

Fig. 30.3 Schematic illustration of the events involved in the formation of tablets with a rotary press.

Fig. 30.4 Diagram of punch tracks of a rotary tablet press. UR, upper roller; LR, lower roller; W, powder volume adjuster; F, feed frame with granules. U1 to U8, upper punches in raised position; L1, lower punch at top position, tablet ejected; L2 to L7, lower punches dropping to lowest position and filling die with granules to an overfill at L7; L8, lower punch raised to expel excess granules giving correct volume; U9 to U12, upper punches lowering to enter die at U12; L13 and U13, upper and lower punches pass between rollers and granules are compacted to a tablet; U14 to U16, upper punch rising to top position; L14 to L16, lower punch rising to eject tablet.

The powder is held in a hopper whose lower opening is located just above the die table. The powder flows by gravity onto the die table and is fed into the die by a feed frame. The reproducibility of the die feeding can be improved by a rotating device, referred to as a force-feeding device. During powder compression both punches operate by vertical movement. After tablet ejection, the tablet is knocked away as the die passes the feed frame.

Computerized hydraulic press

For computerized hydraulic presses the movement of the punches can be controlled and varied considerably. Thus, tablets can be prepared under controlled conditions with respect to the loading pattern and loading rate. Possible applications are the investigation of the sensitivity of a drug to such variations, or to mimic the loading pattern of production presses to predict scale-up problems. Because of this latter application, this type of press is also referred to as a ‘compaction simulator’.

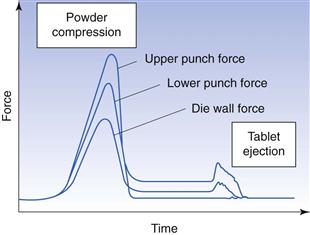

Instrumentation of tablet presses

Significant research on the process of tablet preparation was initiated in the 1950s and 1960s, i.e. about 100 years after the introduction of tablets as a dosage form. An important step in the development of such fundamental research was the introduction of instrumented tablet machines. By this instrumentation, the forces involved in the compaction process, i.e. the press forces from the upper and lower punches, and the force transmitted to the die as well as the displacement of the upper and lower punch during the compression and decompression phases, could be recorded.

Instrumented presses are used in research, in development and in the production of tablets. In research and development, instrumented machines are used to provide fundamental information on the mechanical and compaction properties of powders that should be used in tablet formulations. With this application, the work is normally carried out by instrumented single-punch presses or instrumented hydraulic presses (compaction simulators). The two main applications for an instrumented press in research and development are:

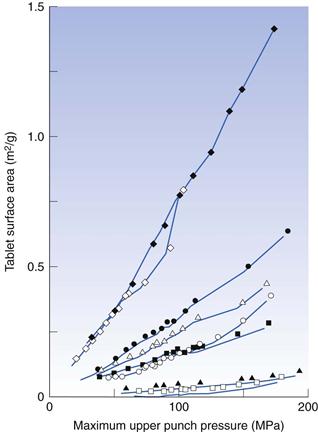

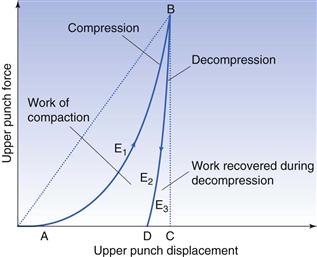

1. To prepare tablets under defined conditions, e.g. in terms of applied force during compaction. These tablets are thereafter characterized by different procedures, such as imaging, surface area and tensile strength analysis

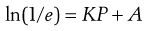

2. To describe and analyse the compression properties of materials by studying punch forces and punch displacements during the compression and decompression phases. A series of different procedures exists, involving, for example, the assessment of deformation behaviour of particles during compression and friction properties during ejection. Some of these are described below.

In production, instrumented production machines, i.e. rotary presses, are used to control the tableting operation and to ensure that tablets of consistent quality are produced. Normally, only force signals are used on production machines and the variation in force signal during compression is monitored as it reflects variations in tablet weight.

Force transducers commonly used in the instrumentation of tablet machines are of two types. The most common type is called a strain gauge, which consists of wires through which an electric current is passed. The strain gauge is bonded to a punch or punch holder. During powder compression, a force is applied to the punches and they will temporarily deform. The magnitude of this deformation is dependent on the elastic modulus of the punches and the force applied. When the punch is deformed, the wire of the strain gauge is also deformed and the electrical resistance of the strain gauge will change. This change in electrical resistance can be recorded and calibrated in terms of a force signal. Another, less common type of force transducer employs piezoelectric crystals. These are devices which emit an electrical charge when loaded, the magnitude of which is proportional to the applied force.

Displacement transducers measure the distance which the punches travel during the compression and decompression processes. The most common type of displacement transducer delivers an analogue signal. It consists of a rod and some inductive elements mounted in a tube. When the rod moves within the tube, a signal is obtained which directly reflects the position of the rod. The movable rod is connected to the punch so that they move in parallel, i.e. the signal from the displacement transducer reflects the position of the punch. Digital displacement transducers are also used in instrumented tablet machines. Such transducers are based on differences in signal level depending on the position of an indicator.

Displacement transducers are necessarily mounted some distance from the punch tip. There is therefore a difference in the position given by the transducer and the real position of the punch tip owing to deformation of the punch along the distance between its tip and the connection point of the transducer. This deviation must be determined by a calibration procedure, e.g. by compressing the punch tips against each other, and a correction for this error must be made before the displacement data can be used.

The signals from the force and displacement transducers are normally amplified and sampled into a computer. After conversion into digital form, the signals are transformed into physically relevant units, i.e. N, Pa, mm, etc., and organized as a function of time. To obtain reliable data, the calibration of the signals, the resolution of the measuring systems and the reproducibility of the values must be carefully considered.

Tablet tooling

Tablets are formed in a variety of shapes. The most common tablet shapes are circular, oval and oblong but tablets may also have other shapes, such as triangular or quadratic. From a side-view, tablets may be flat or convex and with or without bevelled edges. Tablets may also bear break marks or symbols and other markings. Break marks (or breaklines) are used to facilitate breaking of tablets in a controlled way to ensure reproducible doses. Markings are used to facilitate identification of a preparation and are of two types: embossed and debossed. Debossed markings are indented into the tablet and embossed markings are raised on the tablet surface. The size, shape and appearance of a tablet formed by powder compaction are controlled by the set of tools and by tooling design; a large variation in tablet size, shape and appearance can thus be obtained.

Punches and dies for rotary presses are designed in a standardized way and standard configurations and terms are in use. The terminology used in describing the punches includes head, neck, barrel, stem and tip and in describing the die includes face, chamfer and bore. The tools are normally fabricated in steel and different steels may be used. Due to the high forces applied to the powder bed, tools may be damaged and under normal use they become worn. The toughness, wear resistance and corrosiveness vary between different types of steels and the choice of steel grade depends on factors such as the tooling configuration, the formulation to be compacted and the cost. In addition, the surface of punches and dies may be coated with a thin layer of another metal, such as chrome, to modify its surface properties, such as hardness and corrosiveness.

Punches and dies are precision tools and they should thus be handled and stored with care. Manufacturing problems may be related to the quality of the compression tooling. Tooling inspection programmes should thus be used in the development and production of tablets.

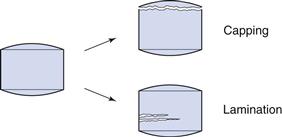

Technical problems during tableting

A number of technical problems can arise during the tableting procedure, among which the most important are:

• high weight and dose variation of the tablets

• low mechanical strength of the tablets

• capping and lamination of the tablets

Such problems are related to the properties of the powder intended to be formed into tablets and also to the design and conditions of the press and the tooling. They should therefore be avoided by ensuring that the powder possesses adequate technical properties and also that a suitable, well-conditioned tablet press is used, e.g. in terms of the use of forced-feed devices and polished and smooth dies and punches.

Important technical properties of a powder that must be controlled to ensure the success of a tableting operation are:

The technical properties of the powder are controlled by the ingredients of the formulation (i.e. the drug and excipients) and by the way in which the ingredients are combined into a powder during precompaction processing. The precompaction processing often consists of a series of unit operations in sequence. The starting point is normally the drug in a pure, most often crystalline form; the subsequent treatment of the drug particles is sometimes referred to as downstream processing. The unit operations used during this precompaction treatment are mainly particle size reduction, powder mixing, particle size enlargement and powder drying. For further details of these procedures see Chapters 10, 11, 28 and 29, respectively. Granulation of a fine powder is a common means used to preserve the fineness of the drug within larger particles that are suitable for tableting (see below) and granulation procedures are traditionally in common use in preparing a powder for tableting. To save time and energy, precompaction processing without a particle size enlargement operation is chosen if possible. This procedure is called tablet production by direct compression or direct compaction.

Tablet production via granulation

Rationale for granulating powders prior to tableting

Because both granulation and tableting involve the formation of aggregates, tablet production by granulation is based on the combination of two size enlargement processes in sequence. The main rationales for granulating the powder (drug and filler mixture) before tableting are to:

• increase the bulk density of the powder mixture and thus ensure that the required volume of powder can be filled into the die

• improve the flowability of the powder in order to ensure that tablets with a low and acceptable tablet weight variation can be prepared

• improve mixing homogeneity and reduce segregation by mixing small particles which subsequently adhere to each other

• improve the compactability of the powder by adding a solution binder, which is effectively distributed on the particle surfaces

• ensure a homogeneous colour in a tablet by adding the colour in a manner that ensures its effective distribution over the particle surfaces

• affect the dissolution process for hydrophobic, poorly soluble particles by using a fine particulate drug which is thoroughly mixed with a hydrophilic filler and a hydrophilic binder.

Before granulation, the drug might be processed separately in order to obtain a suitable quality in terms of solid-state and particulate properties, such as spray drying and milling. Normally, the drug exists in dry particulate form before granulation. However, it might be suspended or dissolved in a liquid and be added to the filler as a part of the agglomeration liquid.

Different procedures may be used for granulation, among which the most important are the use of convective mixers, fluidized-bed driers, spray driers and compaction machines. Chapter 28 discusses granulation in some detail but the process is summarized here in the context of tableting.

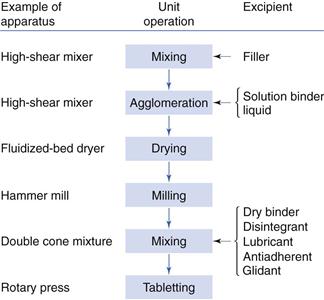

Granulation by convective mixing

Agitation of a powder by convection in the presence of a liquid, followed by drying, is the main procedure for the preparation of pharmaceutical granules. This is often considered to be the most effective means in terms of production time and cost to prepare good-quality granules. The process is often referred to as wet granulation.

The ingredients to be granulated in a convective mixer are first dry mixed. The objective is to achieve a good homogeneity. As the components are often cohesive powders, a convective mixer operating at high intensity is normally used (a high-shear mixer). The mixture often consists of the drug and a filler. A disintegrant may also be included (i.e. an intragranular disintegrant) but it is also common to add the disintegrant to the dry granulation (i.e. an extragranular disintegrant). After wet mixing, the wet mass is dried in a separate drier (usually a fluidized-bed dryer; see Chapter 29). Because granulation in a convective mixer is not a very well-controlled operation, large granules (above 1 mm) are often formed which must be broken down into smaller units. This is normally done by milling in a hammer mill or by pressing the granulation through a screen in an oscillating granulator. Granules ranging in size from about 100 to 800 µm are thus obtained.

The prepared granules are finally dry-mixed with the other ingredients, for example in a double-cone mixer, before tableting. Common excipients added in this final mixing operation are disintegrants, lubricants, glidants and colourants. Figure 30.5 summarizes the sequence of unit operations used in the production of tablets with pre-compaction treatment by granulation.

Alternative granulation procedures

A series of alternative granulation procedures may be preferable in certain situations. Granulation in a fluidized-bed apparatus is less common than the use of convective mixers as it is considered to be more time-consuming. However, granules of high quality in terms of homogeneity, flowability and compactability can be prepared by this operation.

By spray drying a suspension of drug particles in a liquid, which can contain a dissolved binder, relatively small spherical granules with uniform size can be prepared. The process is of limited use, except for the preparation of fillers or diluents for direct compaction. The granulation can show a good compactability and this presents the possibility of granulating a drug suspension without a separate drying step for the drug substance.

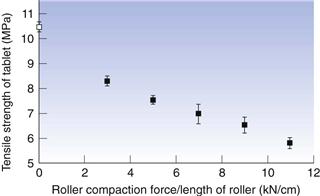

The formation of granules by compacting the powder into large compacts which are subsequently comminuted into smaller granules is an alternative approach to granulation. The approach can be employed as a means of avoiding exposure of the powder to moisture and heat and is also referred to as dry granulation. In addition, for powders of very low bulk density, compaction can be an effective means to increase markedly their bulk density. The formation of the compacts can be accomplished by powder compression in a die (slugging), giving relatively large tablet-like compacts, or by powder compression between rotating rollers (roller compaction), giving weak compacts with a flake or ribbon-like appearance. Roller compaction is a suitable operation for continuous granulation.

Tablet production by direct compaction

An obvious way to reduce production time and hence cost is to minimize the number of operations involved in the pretreatment of the powder mixture before tableting. Tablet production by direct compaction can be reduced to only two operations in sequence: powder mixing and tableting (Fig. 30.6). The advantage with direct compaction is primarily a reduced production cost. However, in a direct compactable formulation, specially designed fillers and dry binders are normally required, which are usually more expensive than the traditional ones. They may also require a larger number of quality tests before processing. As heat and water are not involved, product stability can be improved. Finally, drug dissolution might be faster from a tablet prepared by direct compaction owing to fast tablet disintegration into primary drug particles.

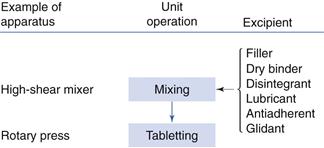

Fig. 30.6 Overview of the sequence of unit operations used in the production of tablets by direct compaction.

The disadvantages of direct compaction are mainly technological. In order to handle a powder of acceptable flowability and bulk density, relatively large particles must be used which may be difficult to mix to a high homogeneity and may be prone to segregation. Moreover, a powder consisting mainly of drug will be difficult to form into tablets if the drug itself has poor compactability. Finally, a uniform colouring of tablets can be difficult to achieve with a colourant in dry particulate form.

Direct compaction may be considered in two common formulation cases; firstly, relatively soluble drugs which can be processed as coarse particles (to ensure good flowability) and secondly, relatively potent drugs which are present in a few milligrams in each tablet and can be mixed with relatively coarse excipient particles (in this latter case the flow and compaction properties of the formulation are mainly controlled by the excipients).

Tablet excipients

In addition to the active ingredient(s), a series of excipients is normally included in a tablet; their role is to ensure that the tableting operation can run satisfactorily and that tablets of specified quality are prepared. Depending on the intended main function, excipients to be used in tablets are subcategorized into different groups. However, one excipient can affect the properties of a powder or the tablet in a series of ways and many substances used in tablet formulations can thus be described as multifunctional. The functions of the most common types of excipients used in tablets are described below. Examples of substances used as excipients in tablets are given in Table 30.1.

Table 30.1

Examples of substances used as excipients in tablet formulation

| Type of excipient | Example of substances |

| Filler | Lactose |

| Sucrose | |

| Glucose | |

| Mannitol | |

| Sorbitol | |

| Calcium phosphate | |

| Calcium carbonate | |

| Cellulose | |

| Disintegrant | Starch |

| Cellulose | |

| Crosslinked polyvinyl pyrrolidone | |

| Sodium starch glycolate | |

| Sodium carboxymethyl cellulose | |

| Solution binder | Gelatin |

| Polyvinyl pyrrolidone | |

| Cellulose derivatives | |

| (e.g. hydroxypropylmethyl cellulose) | |

| Polyethylene glycol | |

| Sucrose | |

| Starch | |

| Dry binder | Cellulose |

| Methyl cellulose | |

| Polyvinyl pyrrolidone | |

| Polyethylene glycol | |

| Glidant | Silica |

| Magnesium stearate | |

| Talc | |

| Lubricant | Magnesium stearate |

| Stearic acid | |

| Polyethylene glycol | |

| Sodium lauryl sulfate | |

| Sodium stearyl fumarate | |

| Liquid paraffin | |

| Antiadherent | Magnesium stearate |

| Talc | |

| Starch | |

| Cellulose |

Filler (or diluent)

In order to form tablets of a size suitable for handling, a lower limit in terms of powder volume and weight is required. Tablets normally weigh at least 50 mg. Therefore, a low dose of a potent drug requires the incorporation of a substance into the formulation to increase the bulk volume of the powder and hence the size of the tablet. This excipient, known as the filler or the diluent, is not necessary if the dose of the drug per tablet is high.

The ideal filler should fulfil a series of requirements, such as:

• possess good biopharmaceutical properties (e.g. water soluble or hydrophilic)

• possess good technical properties (such as compactability and dilution capacity)

As all these requirements cannot be fulfilled by a single substance, different substances have gained use as fillers in tablets, mainly carbohydrates but also some inorganic salts.

Lactose is the most common filler in tablets. It possesses a series of good filler properties, e.g. dissolves readily in water, has a pleasant taste, is non-hygroscopic, is fairly non-reactive and shows good compactability. Its main limitation is that some people have an intolerance to lactose.

Lactose exists in both crystalline and amorphous forms. Crystalline lactose is formed by precipitation and, depending on the crystallization conditions, α-monohydrate or β-lactose (an anhydrous form) can be formed. By thermal treatment of the monohydrate form, crystalline α-anhydrous particles can be prepared. Depending on the crystallization conditions and the use of subsequent size reduction by milling, lactose of different particle sizes is obtained.

Amorphous lactose can be prepared by spray drying a lactose solution (giving nearly completely amorphous particles) or a suspension of crystalline lactose particles in a lactose solution (giving aggregates of crystalline and amorphous lactose). Amorphous lactose dissolves more rapidly than crystalline and shows better compactability. Its main use is therefore in the production of tablets by direct compaction. Amorphous lactose is, however, hygroscopic and physically unstable, i.e. it will spontaneously crystallize if crystallization conditions are met as a result of elevated temperature or high relative humidity (see Chapter 8 for more details).

Other sugars or sugar alcohols, such as glucose, sucrose, sorbitol and mannitol, have been used as alternative fillers to lactose, primarily in lozenges or chewable tablets because of their pleasant taste. Mannitol has a negative heat of solution and imparts a cooling sensation when sucked or chewed.

Apart from the sugars, perhaps the most widely used fillers are powdered celluloses of different types. Celluloses are biocompatible, chemically inert and have good tablet-forming and disintegrating properties. They are therefore also used as dry binders and disintegrants in tablets. They are compatible with many drugs but, owing to their hygroscopicity, may be incompatible with drugs prone to chemical degradation in the solid state.

The most common type of cellulose powder used in tablet formulation is microcrystalline cellulose. The name indicates that the particles have both crystalline and amorphous regions, depending on the relative position of the cellulose chains within the solid. The degree of crystallinity may vary depending on the source of the cellulose and the preparation procedure. The degree of crystallinity will affect the physical and technical properties of the particles, e.g. in terms of hygroscopicity and powder compactability.

Microcrystalline cellulose is prepared by hydrolysis of cellulose followed by spray drying. The particles thus formed are aggregates of smaller cellulose fibres. Depending on the preparation conditions, aggregates of different particle size can be prepared which have different flowabilities.

A final important example of a common filler is an inorganic substance, dicalcium phosphate dihydrate. This is insoluble in water and non-hygroscopic, but is hydrophilic, i.e. easily wetted by water. The substance can be obtained in both a fine particulate form, mainly used in granulation, and an aggregated form. The latter possesses good flowability and is used in tablet production by direct compaction. Calcium phosphate is slightly alkaline and may thus be incompatible with drugs sensitive to alkaline conditions.

Matrix former

In order to affect or control the release of the drug from the tablet, i.e. to speed up or to slow down its release rate, the drug may be dispersed or embedded in a matrix formed by an excipient or a combination of excipients. This type of excipient may thus be referred to as a matrix former. An alternative term is base, a term used in the European Pharmacopoeia (2011) and there defined as ‘the carrier, composed of one or more excipients, for the active substance(s) in semi-solid and solid preparations’.

The matrix former is often a polymer or a lipid and may constitute a significant fraction of the total tablet weight. When the objective is to increase drug dissolution, the matrix former can be a water-soluble substance or a lipid and the drug is dissolved or suspended as fine particles in the matrix. An example of a water-soluble matrix former is poly ethylene glycol (PEG). When the objective is to prolong the drug release, the matrix former can be either an insoluble substance (a polymer or a lipid) or a substance that forms a gel in contact with water. The drug is normally dispersed in particulate form in the matrix (for more details, see below). A common gel-forming substance in tablets is hydroxy propyl methyl cellulose (HPMC). Matrix formers are discussed in more detail in Chapter 31.

Disintegrant

A disintegrant is included in the formulation to ensure that the tablet, when in contact with a liquid, breaks up into small fragments, which promotes rapid drug dissolution. Ideally, the tablet should break up into individual drug particles in order to obtain the largest possible effective surface area during dissolution.

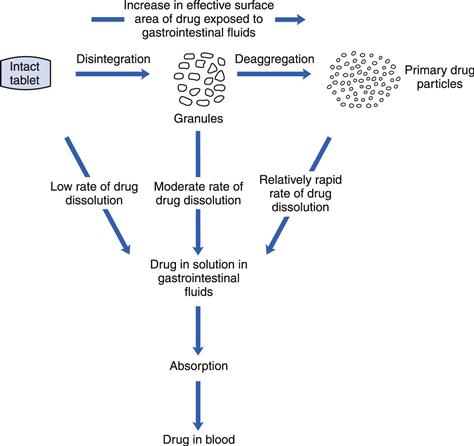

The disintegration process for a tablet occurs in two steps. First, the liquid wets the solid and penetrates the pores of the tablet. Thereafter, the tablet breaks into smaller fragments. The actual fragmentation of the tablet can also occur in steps, i.e. the tablet disintegrates into aggregates of primary particles which subsequently deaggregate into their primary drug particles. A deaggregation directly into primary powder particles will set up conditions for the fastest possible dissolution of the drug. A scheme for the release of the drug from a disintegrating tablet is shown in Figure 30.7.

Fig. 30.7 Mechanistic representation of the drug release process from a tablet by disintegration and dissolution. (Courtesy of Wells and Rubinstein, 1976, with permission.)

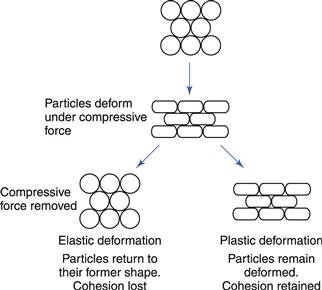

Several mechanisms of action of disintegrants have been suggested, such as swelling of particles, exothermic wetting reaction, particle repulsion and particle deformation recovery. However, as two main processes are involved in the disintegration event, disintegrants to be used in plain tablets are here classified into two types:

1. Disintegrants that facilitate water uptake. These disintegrants act by facilitating the transport of liquids into the pores of the tablet, with the consequence that the tablet may break into fragments. One obvious type of substance that can promote liquid penetration is surface-active agents. Such substances are used to make the drug particle surfaces more hydrophilic and thus promote the wetting of the solid and the penetration of the liquid into the pores of the tablet. It has also been suggested that other substances can promote the liquid penetration, using capillary forces to suck water into the pores of the tablet.

2. Disintegrants that will rupture the tablet. Rupturing of tablets can be caused by swelling of the disintegrant particles during sorption of water. However, it has also been suggested that non-swelling disintegrants can break the tablet and different mechanisms have been suggested. One such concerns a repulsion of particles in contact with water and another the recovery of deformed particles to their original shape in contact with water, i.e. particles which have been deformed during compaction.

The disintegrant most traditionally used in conventional tablets is starch, among which potato, maize and corn starches are commonly used. The typical concentration range of starch in a tablet formulation is up to 10%. Starch particles swell in contact with water and this swelling can subsequently disrupt the tablet. However, it has also been suggested that starch particles may facilitate disintegration by particle-particle repulsion.

The most common and effective disintegrants act via a swelling mechanism and a series of effective swelling disintegrants has been developed which can swell dramatically during water uptake and thus quickly and effectively break the tablet. These are normally modified starch or modified cellulose. High-swelling disintegrants are included in the formulation at relatively low concentrations, typically 1–5% by weight.

Disintegrants can be mixed with other ingredients prior to granulation and thus be incorporated within the granules (intragranular addition). It is also common for the disintegrant to be mixed with the dry granules before the complete powder mix is compacted (extragranular addition). The latter procedure will contribute to an effective disintegration of the tablet into smaller fragments.

A third group of disintegrants functions by producing gas, normally carbon dioxide, when in contact with water. Such disintegrants are used in effervescent tablets and normally not in tablets that should be swallowed as a solid. The liberation of carbon dioxide is obtained by the decomposition of bicarbonate or carbonate salts in contact with acidic water. The acidic pH is accomplished by the incorporation of a weak acid in the formulation, such as citric acid and tartaric acid.

Dissolution enhancer

For drugs of low aqueous solubility, the dissolution of the drug may be the rate-limiting step in the overall drug release and absorption processes. Agents, other than matrix formers, may therefore sometimes be found in the composition of a tablet with the role to speed up the drug dissolution process by temporarily increasing the solubility of the drug during drug dissolution. An important example of a dissolution enhancer is the incorporation into the formulation of a substance that forms a salt with the drug during dissolution, e.g. increasing the dissolution rate of aspirin by using magnesium oxide in the formulation.

Absorption enhancer

For drugs with poor absorption properties, the absorption can be affected (see Chapter 20) by using substances in the formulation that affect the permeability of the intestinal cell membrane and thus increase the rate at which the drug passes though the intestinal membrane. An additive that modulates the permeability of the intestine is often referred to as an absorption enhancer.

Binder

A binder (also sometimes called an adhesive) is added to a drug-filler mixture to ensure that granules and tablets can be formed with the required mechanical strength. Binders can be added to a powder in different ways:

• As a dry powder which is mixed with the other ingredients before wet agglomeration. During the agglomeration procedure, the binder might thus dissolve partly or completely in the agglomeration liquid

• As a solution which is used as agglomeration liquid during wet agglomeration. The binder is here often referred to as a solution binder

• As a dry powder which is mixed with the other ingredients before compaction (slugging or tableting). The binder is here often referred to as a dry binder.

Both solution binders and dry binders are included in the formulation at relatively low concentrations, typically 2–10% by weight. Common traditional solution binders are starch, sucrose and gelatin. More commonly used binders today, with improved adhesive properties, are polymers such as polyvinylpyrrolidone and cellulose derivatives (in particular hydroxypropyl methylcellulose). Important examples of dry binders are microcrystalline cellulose and crosslinked polyvinylpyrrolidone.

Solution binders are generally considered the most effective and this is therefore the most common way of incorporating a binder into granules; the granules thus formed are often referred to as binder–substrate granules. It is not uncommon, however, for a dry binder to be added to the dry binder–substrate granules before tableting in order to further improve the compactability of the granulation.

Glidant

The role of the glidant is to improve the flowability of the powder. Glidants are used in formulations for direct compaction but are often also added to granules before tableting to ensure that sufficient flowability of the tablet mass is achieved for high production speeds.

Traditionally, talc has been used as a glidant in tablet formulations, in concentrations of about 1–2% by weight. Today, the most commonly used glidant is probably colloidal silica, added in very low proportions (about 0.2% by weight). Because the silica particles are very small they adhere to the particle surfaces of the other ingredients (i.e. an ordered or structured mixture is formed; see Chapter 11) and improve flow by reducing interparticulate friction. Magnesium stearate, normally used as a lubricant, can also promote powder flow at low concentrations (<1% by weight).

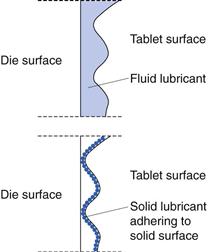

Lubricant

The function of the lubricant is to ensure that tablet formation and ejection can occur with low friction between the solid and the die wall. High friction during tableting can cause a series of problems, including inadequate tablet quality (capping or even fragmentation of tablets during ejection and vertical scratches on tablet edges) and may even stop production. Lubricants are thus included in almost all tablet formulations.

Lubrication is achieved mainly by two mechanisms: fluid lubrication and boundary lubrication (Fig. 30.8). In fluid lubrication a layer of fluid is located between and separates the moving surfaces of the solids from each other and thus reduces the friction. Fluid lubricants are seldom used in tablet formulations. However, liquid paraffin has been used, for instance in formulations for effervescent tablets.

Boundary lubrication is considered as a surface phenomenon, as here the sliding surfaces are separated by only a very thin film of lubricant. The nature of the solid surfaces will therefore affect friction. In boundary lubrication, the friction coefficient and wear of the solids are higher than with fluid lubrication. All substances that can affect the interaction between sliding surfaces can be described as boundary lubricants, including adsorbed gases. The lubricants used in tablet formulations acting by boundary lubrication are fine particulate solids.

A number of mechanisms have been discussed for these boundary lubricants, including that lubricants are substances that show a low resistance towards shearing. The most effective of the boundary lubricants are stearic acid or stearic acid salts, such as magnesium stearate. Magnesium stearate has become the most widely used lubricant owing to its superior lubrication properties. The stearic acid salts are normally used at low concentrations (<1% by weight).

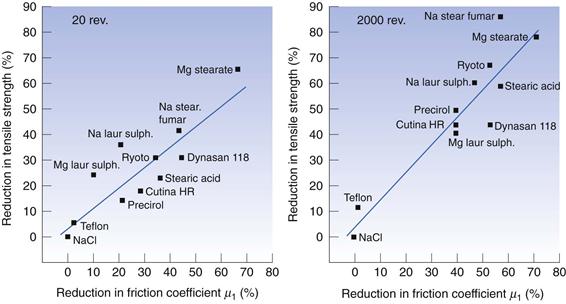

Besides reducing friction, lubricants may cause undesirable changes in the properties of the tablet. The presence of a lubricant in a powder is thought to interfere in a deleterious way with the bonding between the particles during compaction, thus reducing tablet strength (Fig. 30.9). Because many lubricants are hydrophobic, tablet disintegration and dissolution are often retarded by the addition of a lubricant. These negative effects are strongly related to the amount of lubricant present and a minimum amount is normally used in a formulation, i.e. concentrations of 1% or below. In addition, the way in which the lubricant is mixed with the other ingredients should also be considered. It can, for example, be important if the excipients are added sequentially to a granulation rather than simultaneously. The total mixing time and the mixing intensity are also important in this context.

Fig. 30.9 The reduction in tablet tensile strength as a function of the reduction in friction coefficient during tableting of a sodium chloride powder mixed with 0.1% by weight of a series of lubricants admixed at two different mixing intensities. (Courtesy of Hölzer and Sjögren, 1981, with permission.)

The commonly observed retardation of disintegration and dissolution of tablets is related to the hydrophobic character of the most commonly used lubricants. In order to avoid these negative effects, more hydrophilic substances have been suggested as alternatives to the hydrophobic lubricants. Examples are surface-active agents and polyethylene glycol. A combination of hydrophobic and hydrophilic substances might also be used.

The lubricant’s effect on friction and on the changes in tablet properties is related to the tendency of lubricants to adhere to the surface of drugs and fillers during dry mixing. Lubricants are often fine particulate substances which thus are prone to adhere to larger particles. In addition, studies on the mixing behaviour of magnesium stearate have indicated that this substance has the ability to form a film which can cover a fraction of the surface area of the drug or filler particles (the substrate particles). This film can be described as being continuous rather than particulate. A number of factors have been suggested to affect the development of such a lubricant film during mixing and hence also affect friction and changes in tablet properties, such as the shape and surface roughness of the substrate particles; the surface area of the lubricant particles; mixing time and intensity; and the type and size of mixer.

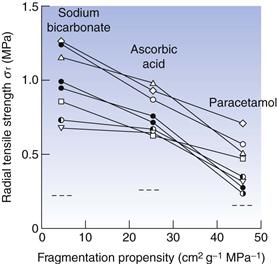

Concerning the tablet strength-reducing effect of a lubricant, apart from the degree of surface coverage of the lubricant film obtained during mixing, the compression behaviour of the substrate particles will also be important. Drugs and fillers can thus be evaluated in terms of their lubricant sensitivity, i.e. the reduction in tablet strength due to the addition of a lubricant compared to a tablet formed from a powder without a lubricant. An important property for this lubricant sensitivity seems to be the degree of fragmentation the substrate particles undergo during compression (see below). It is thus assumed that, during compression, particle surfaces which are not covered with a lubricant film are formed during particle fragmentation and that these clean surfaces will bond differently from the lubricant-covered particle surfaces.

To explain the effect of lubricant film formation on the tensile strength of tablets, a coherent matrix model has been developed. This suggests that when a continuous matrix of lubricant-covered particle surfaces exists in a tablet, along which a fracture plane can be formed, the tablet strength is considerably lower than that of tablets formed from unlubricated powder. However, if the mixing and compression processes do not result in such a coherent lubricant matrix within the tablet, for example due to irregular substrate particles or particle fragmentation, the lubricant sensitivity appears to be lower.

Antiadherent

The function of an antiadherent is to reduce adhesion between the powder and the punch faces and thus prevent particles sticking to the punches. Many powders are prone to adhere to the punches, a phenomenon (known in the industry as sticking or picking) which is affected by the moisture content of the powder. Such adherence is especially prone to happen if the tablet punches have markings or symbols. Adherence can lead to a build-up of a thin layer of powder on the punches, which in turn will lead to an uneven and matt tablet surface with unclear markings or symbols.

Many lubricants, such as magnesium stearate, also have antiadherent properties. However, other substances with limited ability to reduce friction can also act as antiadherents, such as talc and starch.

Sorbent

Sorbents are substances that are capable of sorbing some quantities of fluids in an apparently dry state. Thus, oils or oil-drug solutions can be incorporated into a powder mixture which is granulated and compacted into tablets. Microcrystalline cellulose and silica are examples of sorbing substances used in tablets.

Flavour

Flavouring agents are incorporated into a formulation to give the tablet a more pleasant taste or to mask an unpleasant one. The latter can also be achieved by coating the tablet or the drug particles.

Flavouring agents are often thermolabile and so cannot be added prior to an operation involving heat. They are often mixed with the granules as an alcohol solution.

Colourant

Colourants are added to tablets to aid identification and patient compliance. Colouring is often accomplished during coating (see Chapter 32 for further information) but a colourant can also be included in the formulation prior to compaction. In the latter case, the colourant can be added as an insoluble powder or dissolved in the granulation liquid. The latter procedure may lead to a colour variation in the tablet caused by migration of the soluble dye during the drying stage (see Chapter 29 for more information on the phenomenon of solute migration).

Tablet types

Classification of tablets

Several categories of tablets may be distinguished and the denomination and definitions of different types of tablets can be found in pharmacopoeias. The tablet dosage forms described in the European Pharmacopoeia (2011) appear in the monographs for tablets and for oromucosal preparations (the monograph on oromucosal preparations includes some types of tablets, i.e. compressed lozenges, sublingual tablets and buccal tablets that are intended for administration to the oral cavity and/or the throat to obtain a local or systemic effect).

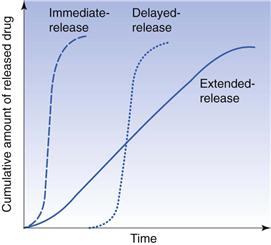

A common means of classifying tablets is based on the drug release pattern from the tablets. The following categories are often used in this context: immediate release, prolonged release, pulsatile release and delayed release. The latter three types are also referred to as modified-release tablets.

For immediate-release tablets, the drug is intended to be released rapidly after administration, or the tablet is dissolved in liquid before intake and thus administered as a solution. Immediate-release tablets are the most common type of tablet and include disintegrating, chewable, effervescent, sublingual and buccal tablets.

Modified-release tablets should normally be swallowed intact. The formulation and thus also the type of excipients used in such tablets might be quite different from those of immediate-release tablets. The term prolonged-release tablet is used to indicate that the drug is released slowly at a nearly constant rate. If the rate of release is constant during a substantial period of time, a zero-order type of release is obtained, i.e. M = kt (where M is the cumulative amount of drug released and t is the release time). This is sometimes described as an ideal type of prolonged-release preparation.

A pulsatile release is another means to increase the time period for drug absorption after a single administration and is accomplished by releasing the drug in two or more pulses.

For delayed-release tablets the drug is liberated from the tablet some time after administration. After this period has elapsed, the release is normally rapid. The most common type of delayed-release tablet is a gastro-resistant (also known as enteric-coated) tablet, for which the drug is released in the upper part of the small intestine after the preparation has passed the stomach. However, a delayed release can also be combined with a prolonged drug release, e.g. for local treatment in the lower part of the intestine or in the colon.

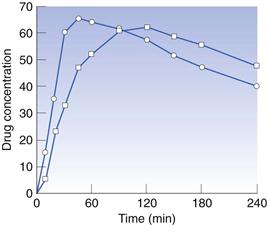

The type of release obtained from immediate-, prolonged- and delayed-release tablets is illustrated in Figure 30.10. In the following sections, the most common types of tablets are described.

Disintegrating tablets

The most common type of tablet is intended to be swallowed and to release the drug in a relatively short time thereafter by disintegration and dissolution, i.e. the goal of the formulation is fast and complete drug release in vivo. Such tablets are often referred to as conventional or plain tablets. A disintegrating tablet includes normally at least the following types of excipients: filler (if the dose of the drug is low), disintegrant, binder, glidant, lubricant and antiadherent.

As discussed above, the drug is released from a disintegrating tablet in a sequence of processes, including tablet disintegration, drug dissolution and drug absorption (see Fig. 30.7). All these processes will affect, and can be rate-limiting steps for, the drug bioavailability. The rate of the processes is affected by both formulation factors and production conditions.

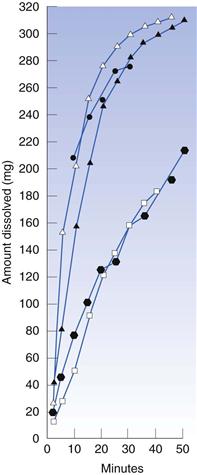

The disintegration time of the tablet is a function of the composition and manufacturing conditions and may thus depend on several factors. Regarding composition, the choice of disintegrant (Fig. 30.11) is of obvious importance but also other excipients, such as the type of filler and lubricant can also be of significant importance for tablet disintegration.

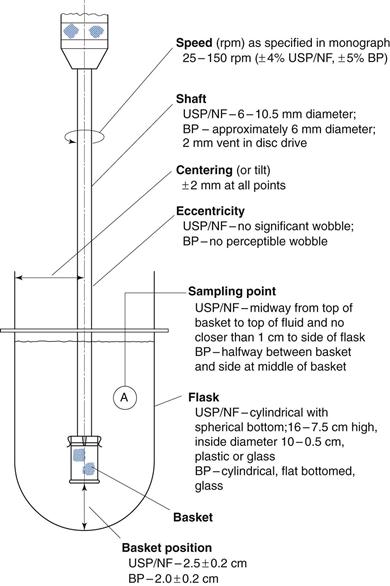

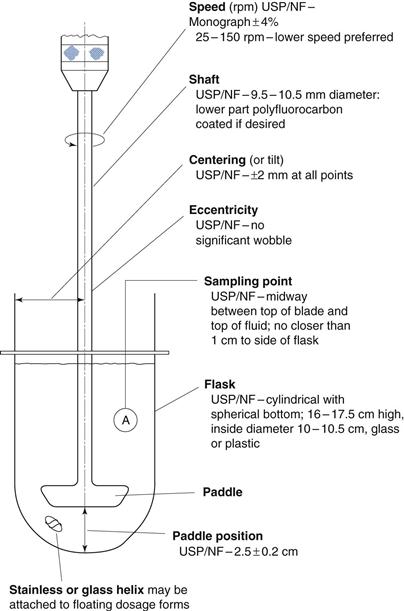

Fig. 30.11 The dissolution rate of salicylic acid, as assessed by an in vitro dissolution method based on agitated baskets, from tablets formed from mixtures of salicylic acid (325 mg) and a series of different types of starches as disintegrant  potato starch,

potato starch,  arrowroot starch,

arrowroot starch,  rice starch, • corn starch, Δ compressible starch. (Courtesy of Underwood and Cadwallader, 1972, with permission.)

rice starch, • corn starch, Δ compressible starch. (Courtesy of Underwood and Cadwallader, 1972, with permission.)

Tablet disintegration may also be affected by production conditions during manufacture. Important examples that may affect tablet disintegration time are the design of the granulation procedure (which will affect the physical properties of the granules), mixing conditions during the addition of lubricants and antiadherents, the applied punch force during tableting and the punch force-time relationship. It has been reported that an increased compaction pressure can either increase or decrease disintegration time, or give complex relationships with maximum or minimum disintegration times.

In many cases, the drug dissolution rate is the rate-limiting step in the drug release process, especially for drugs that are poorly soluble in water but that are readily absorbed in the intestine (i.e. typically class II drugs in the Biopharmaceutics Classification System, see Chapter 21). Since many drugs show very poor solubility, the problem of the rate of drug dissolution is often a critical issue during the development of an immediate release tablet. The most common means to achieve acceptable drug dissolution rate for poorly soluble compounds are:

• control of apparent solubility of the drug.

• control of surface area exposed to the dissolution medium.

The apparent solubility can be increased by changing the solid-state form of the drug, such as a polymorph, using a salt of the drug or using amorphous particles. The surface area of a solid is inversely proportional to particle size and particle size reduction is an obvious means to increase drug dissolution rate. However, a reduced particle size will make a powder more cohesive. A reduction in drug particle size might produce aggregates of particles which are difficult to break up, with the consequence that the drug dissolution rate is not related to the surface area of the primary drug particles. It is thus important to ensure that the tablet is formulated in such a way that it will disintegrate and that the aggregates so formed break up into small drug particles in order that a large surface area of the drug is exposed to the dissolution medium. The preparation and use of small particles, i.e. down to the sub-micrometre range (nano-sized particles), and the use of drug dissolution enhancers and matrix formers in tablet compositions of poorly soluble drugs are important issues in the formulation of disintegrating, immediate-release tablets.

For drugs with poor absorption properties, the absorption can be affected (see Chapter 20) by modifying the drug’s lipophilicity, e.g. by esterification of the drug as well as by adding absorption enhancers.

Single disintegrating tablets can also be prepared in the form of multilayers, i.e. the tablet consists of concentric or parallel layers cohered to each other. Multilayer tablets are prepared by repeated compression of powders and are made primarily to separate incompatible drugs from each other, i.e. incompatible drugs can be incorporated into the same tablet. Although intimate contact exists at the surface between the layers, the reaction between the incompatible drugs is limited. The use of parallel layered tablets where the layers are differently coloured represents an approach to preparing easily identifiable tablets.

Another variation of the disintegrating tablet is coated tablets which are intended to disintegrate and release the drug quickly (in contrast to coated tablets intended for modified release). The rationale for using coated tablets and detailed descriptions of the procedures used for tablet coating are given in Chapter 32.

Chewable tablets

Chewable tablets are chewed and thus are mechanically disintegrated in the mouth. The drug is, however, normally not dissolved in the mouth but swallowed and dissolves in the stomach or intestine. Thus, chewable tablets are used primarily to accomplish a quick and complete disintegration of the tablet – and hence obtain a rapid drug effect – or to facilitate the administration of the tablet. A common example of the former is antacid tablets. In the latter case, the elderly and children in particular have difficulty swallowing tablets and so a chewable tablet is an attractive form of medication. Important examples are vitamin tablets. Another general advantage of a chewable tablet is that this type of medication can be taken when water is not available.

Chewable tablets are similar in composition to conventional tablets except that a disintegrant is normally not included in the composition. Flavouring and colouring agents are common and sorbitol and mannitol are common examples of fillers.

Effervescent tablets

Effervescent tablets are dropped into a glass of water before administration, during which carbon dioxide is liberated. This facilitates tablet disintegration and drug dissolution; the dissolution of the tablet should be complete within a few minutes. As mentioned above, the effervescent carbon dioxide is created by a reaction in water between a carbonate or bicarbonate and a weak acid such as citric or tartaric acids.

Effervescent tablets are used to obtain rapid drug action, for example for analgesic drugs (Fig. 30.12), or to facilitate the intake of the drug, for example for vitamins.

Fig. 30.12 Concentration of salicylates in plasma after administration of acetylsalicylic acid tablets (1 g). Circles, effervescent tablet; squares, conventional tablet. (Courtesy of Ekenved et al, 1975, with permission.)

The amount of sodium bicarbonate in an effervescent tablet is often quite high (about 1 g). After dissolution of such a tablet, a buffered water solution will be obtained which normally temporarily increases the pH of the stomach. The result is a rapid emptying of the stomach and the residence time of the drug in the stomach will thus be short. As drugs are absorbed in the small intestine rather than in the stomach, effervescent tablets can thus show a fast drug absorption, which can be advantageous, for example, for analgesic drugs. Another aspect of the short drug residence time in the stomach is that drug-induced gastric irritation can be avoided, e.g. for aspirin tablets, as the absorption of aspirin in the stomach can cause irritation.

Effervescent tablets also often include a flavour and a colourant. A water-soluble lubricant is preferable in order to avoid a film of a hydrophobic lubricant on the surface of the water after tablet dissolution. A binder is normally not included in the composition.

Effervescent tablets are prepared by both direct compaction and by compaction via granulation. In the latter case, traditional wet granulation is seldom used; instead, granules are formed by the fusion of particles as a result of their partial dissolution during wet massing of a moistened powder.

Effervescent tablets should be packaged in such a way that they are protected against moisture. This is accomplished with waterproof containers, often including a dessicant, or with blister packs or aluminium foils.

Compressed lozenges

Compressed lozenges are tablets that dissolve slowly in the mouth and so release the drug dissolved in the saliva. Lozenges are used for systemic drug uptake or for local medication in the mouth or throat, e.g. with local anaesthetic, antiseptic and antibiotic drugs. The latter type of tablets can thus be described as slow-release tablets for local drug treatment.

Disintegrants are not used in the formulation but otherwise such tablets are similar in composition to conventional tablets. In addition, lozenges are often coloured and include a flavour. The choice of filler and binder is of particular importance in the formulation of lozenges, as these excipients should contribute to a pleasant taste or feeling during tablet dissolution. The filler and binder should therefore be water soluble and have a good taste. Common examples of fillers are glucose, sorbitol and mannitol. A common binder in lozenges is gelatin.

Lozenges are normally prepared by compaction at high applied pressures in order to obtain a tablet of high mechanical strength and low porosity which can dissolve slowly in the mouth.

Sublingual tablets and buccal tablets

Sublingual tablets and buccal tablets are used for drug release in the mouth followed by systemic uptake of the drug. A rapid systemic drug effect can thus be obtained without first-pass liver metabolism. Sublingual tablets are placed under the tongue and buccal tablets are placed in the side of the cheek or high up between the inside of the upper lip and gum.

Sublingual and buccal tablets are often small and porous, the latter facilitating fast disintegration and drug release. Other designs, comprising high molecular weight hydrophilic polymers and/or gums, adhere in place by forming a gel. They remain in position, releasing drug, for 1–2 hours (e.g. prochlorperazine maleate for nausea).

Prolonged-release and pulsatile-release tablets

Classification

In recent years there has been great interest in the development and use of tablets which should be swallowed and thereafter slowly release the drug in the gastrointestinal tract for a period of about 12–24 hours. Such tablets are denominated in various ways, such as slow release, extended release, sustained release and prolonged release. They are often also referred to as controlled-release preparations. This latter term is somewhat misleading, as all tablets, irrespective of their formulation and use, should release the drug in a controlled and reproducible way. The nomenclature for prolonged-release preparations is subject to some debate and no worldwide acceptable system exists. The reader is referred to Chapter 31 for further discussion on this subject.

After release from the tablet, the drug should normally be absorbed into the systemic circulation. The aim is normally to increase the time period during which a therapeutic drug concentration level in the blood is maintained. However, the aim can also be to increase the release time for drugs that can cause local irritation in the stomach or intestine if they are released quickly. Examples of the latter are potassium chloride and iron salts. In addition, drugs for local treatment of diseases in the large intestine are sometimes formulated as prolonged-release tablets.

A prolonged-release preparation can also be categorized as a single-unit or a multiple-unit dosage form. In the first case, the drug dose is incorporated into a single release unit and in the latter is divided into a large number of small release units. A multiple-unit dosage form is often considered to give a more reproducible drug action.

There is a series of rationales behind the increased interest in administering drugs orally for systemic uptake in the form of prolonged-release tablets. However, the drug must fulfil certain criteria in order to render itself suitable for sustained-release medication, otherwise another type of tablet is a more feasible alternative. These rationales and criteria, as well as the pharmacokinetic aspects of prolonged-release drug administration, are described elsewhere in this book (see Chapters 22 and 31). In Chapter 31 the formulation principles used to achieve prolonged drug release are described.

Prolonged-release tablets are often categorized according to the mechanism of drug release. The following are the most common means used to achieve a slow, controlled release of the drug from tablets:

Diffusion-controlled release systems

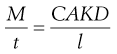

In diffusion-controlled prolonged-release systems, the transport by diffusion of dissolved drugs in pores filled with gastric or intestinal juice or in a solid (normally polymer) phase is the release-controlling process. Depending on the part of the release unit in which the drug diffusion takes place, diffusion-controlled release systems are divided into matrix systems (also referred to as monolithic systems) and reservoir systems. The release unit can be a tablet or a nearly spherical particle of about 1 mm in diameter (a granule or a millisphere). In both cases the release unit should stay more or less intact during the course of the release process. In matrix systems, diffusion occurs in pores located within the bulk of the release unit and in reservoir systems, diffusion takes place in a thin water-insoluble film or membrane, often about 5–20 µm thick, which surrounds the release unit. Diffusion through the membrane can occur in pores filled with fluid or in the solid phase that forms the membrane.

Drug is released from a diffusion-controlled release unit in two steps:

1. The liquid that surrounds the dosage form penetrates the release unit and dissolves the drug. A concentration gradient of dissolved drug is thus established between the interior and the exterior of the release unit.

2. The dissolved drug will diffuse in the pores of the release unit or the surrounding membrane and thus be released or, alternatively, the dissolved drug will partition into the membrane surrounding the dose unit and diffuse in the membrane.

A dissolution step is thus normally involved in the release process but the diffusion step is the rate-controlling step. The rate at which diffusion will occur depends on three variables: the concentration gradient over the diffusion distance; the area and distance over which diffusion occurs; and the diffusion coefficient of the drug in the diffusion medium. Some of these variables are used to modulate the release rate in the formulation.

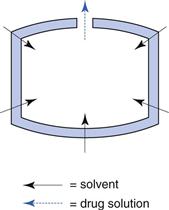

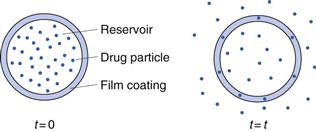

Reservoir systems.

In a reservoir system the diffusion occurs in a thin film surrounding the release unit (Fig. 30.13). This film is normally formed from a high molecular weight polymer. The diffusion distance will be constant during the course of the release and, as long as a constant drug concentration gradient is maintained, the release rate will be constant, i.e. a zero-order release (M = kt).

Fig. 30.13 Schematic illustration of the mechanism of drug release from a diffusion-based reservoir tablet (t = time).

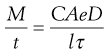

One possible process for the release of the drug from a reservoir system involves partition of the drug dissolved inside the release unit to the solid membrane, followed by transport by diffusion of the drug within the membrane. Finally, the drug will partition to the solution surrounding the release unit. The driving force for the release is the concentration gradient of dissolved drug over the membrane. The release rate can be described in a simplified way by the following equation, which also summarizes the formulation factors by which the release rate can be controlled, i.e.:

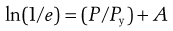

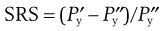

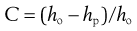

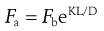

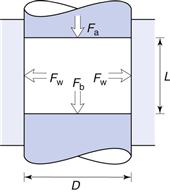

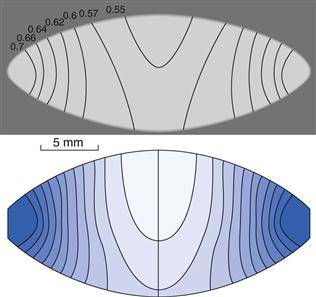

(30.1)

(30.1)

where C is the solubility of the drug in the liquid, A and l are the area and thickness of the membrane, D is the diffusion coefficient of the drug in the membrane, and K the partition coefficient for the drug between the membrane and the liquid at equilibrium.

In practice, the membrane surrounding the release unit often includes a water-soluble component. This can be small particles of a soluble substance, such as sucrose, or a water-soluble polymer, such as a water-soluble cellulose derivative (e.g. hydroxypropyl methylcellulose). In the latter case the polymer is used together with a water-insoluble polymer as the film-forming materials that constitute the coating. In such a membrane, the water-soluble component will dissolve and form pores filled with liquid in which the drug can thereafter diffuse. The area and length of these pores will thus constitute the diffusion area and distance. These factors can be estimated from the porosity of the membrane (e) and the tortuosity (τ) of the pores (the tortuosity refers to the ratio between the actual transport distance in the pores between two positions and the transport distance in a solution). The release rate can thus be described in a simplified way as follows:

(30.2)

(30.2)

The membrane porosity and pore tortuosity can be affected by the addition of water-soluble components to the membrane.

For oral preparations, the film surrounding the release units is normally based on high molecular weight, water-insoluble polymers, such as certain cellulose derivatives (e.g. ethyl cellulose) and acrylates. The film often also includes a plasticizer. In the case of drug release through liquid-filled pores, a small amount of a water-soluble compound is also added, as described above. Reservoir systems today are normally designed as multiple-unit systems rather than single units.

Matrix systems.

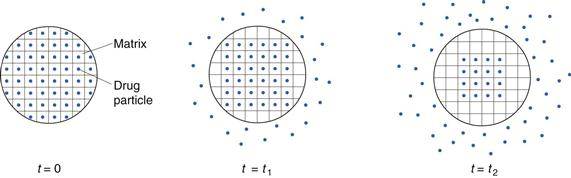

In a matrix system the drug is dispersed as solid particles within a matrix formed of a water-insoluble polymer, such as polyvinyl chloride (Fig. 30.14) or in a matrix forming a gel in contact with water (see below). Initially, drug particles located at the surface of the release unit will be dissolved and the drug released rapidly. Thereafter, drug particles at successively increasing distances from the surface of the release unit will be dissolved and released by diffusion in liquid filled pores of the matrix or in the gel to the exterior of the release unit. Thus, the diffusion distance of dissolved drug will increase as the release process proceeds. The drug release, in terms of the cumulative amount of drug (M) released from a matrix can often be approximated to be proportional to the square root of time, i.e. M = kt1/2.

Fig. 30.14 Schematic illustration of the mechanism of drug release from a diffusion-based matrix tablet (t = time).

The main formulation factors by which the release rate from a matrix system can be controlled are the amount of drug in the matrix, the porosity of the release unit, the length of the pores in the release unit (dependent on the size of the release unit and the pore tortuosity) and the solubility of the drug (which regulates the concentration gradient). The characteristics of the pore system can be affected by, for example, the addition of soluble excipients and by the compaction pressure during tableting.

Matrix systems are traditionally designed as single-unit systems, normally tablets, prepared by tableting. However, alternative preparation procedures are also used, especially for release units that are smaller than tablets. Examples of such techniques are extrusion, spray congealing and casting.

Dissolution-controlled release systems

In dissolution-controlled prolonged-release systems, the rate of dissolution of the drug or another ingredient in the gastrointestinal juices is the release-controlling process. It is obvious that a sparingly water-soluble drug can form a preparation of a dissolution-controlled prolonged-release type. Reduced drug solubility can be accomplished by preparing poorly soluble salts or derivatives of the drug. An alternative means of achieving prolonged release based on the dissolution-control principle is to incorporate the drug in a slowly dissolving carrier or by covering drug particles with a slowly dissolving coating. In the latter case, the release of the drug from such units occurs in two steps:

1. The liquid that surrounds the release unit dissolves the coating (rate-limiting dissolution step).

2. The solid drug is exposed to the liquid and subsequently dissolves.

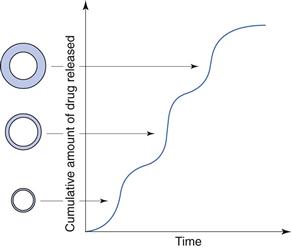

In order to obtain an extended release based on dissolution of a coating, the tablet is formulated to release the drug in a series of consecutive pulses, i.e. a pulsatile release. This can be accomplished by dividing the drug dose into a number of smaller release units, often nearly spherical granules of about 1 mm in diameter, which are coated in such a way that the dissolution time of the coatings will vary (Fig. 30.15). A variation in dissolution time of the coating can be accomplished by varying its thickness or its solubility. Release units with different release times will be mixed and formed into a disintegrating tablet.

Fig. 30.15 Schematic representation of the cumulative amount of drug released from a dissolution-based (due to differences in coating thickness) pulsatile-release preparation.

Delayed-release tablets are normally formulated as dissolution-controlled preparations. In the case of gastro-resistant tablets, the dissolution is inhibited until the preparation reaches the higher pH of the small intestine, where the drug is released in a relatively short time.

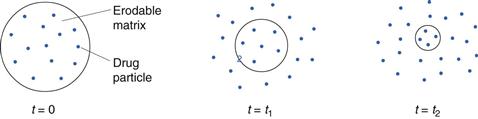

Erosion-controlled release systems

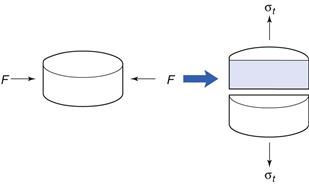

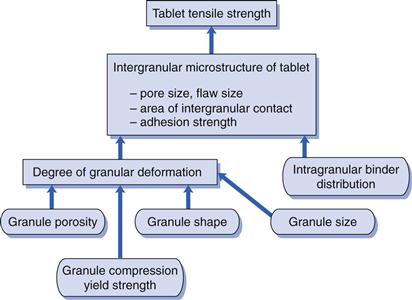

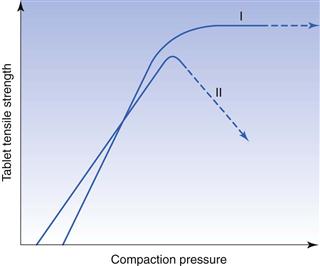

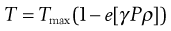

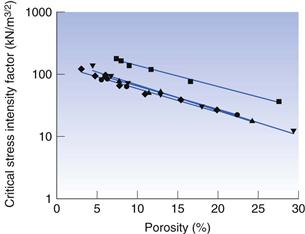

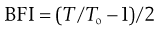

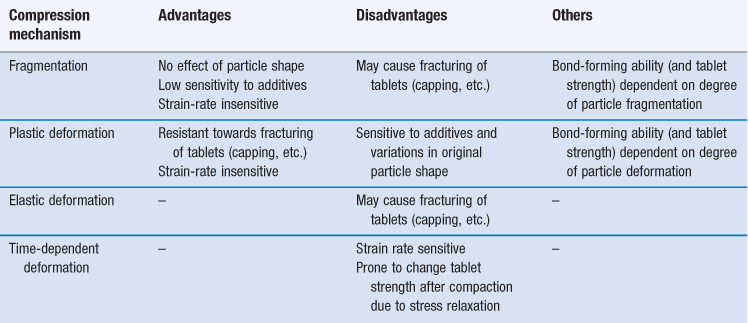

In erosion-controlled prolonged-release systems, the rate of drug release is controlled by the erosion of a matrix in which the drug is dispersed. The matrix is normally formed by a tableting operation and the system can thus be described as a single-unit system. The erosion in its simplest form can be described as a continuous liberation of matrix material (both drug and excipient) from the surface of the tablet, i.e. surface erosion. The consequence will be a continuous reduction in tablet weight during the course of the release process (Fig. 30.16). Drug release from an erosion system can thus be described in two steps: